We specialize in manufacturing

What is pleated filter element?

Here is a detailed explanation of what a pleated filter element is, how it works, and why it's used. Simple Definition A pleated filter element is a type of filter where the filtering media (the material that actually captures contaminants) is folded into a series of uniform "pleats" (like an accordion or a paper fan). This design dramatically increases the surface area available for filtration within a given housing or cartridge size. Key Components & Structure Filter Media: The core material that performs the filtration. This can be made from various materials depending on the application: Polyester or Polypropylene: Common for liquids (oil, fuel, water) and air. Cellulose (Paper): Often used in engine air and oil filters. Glass Fiber: For high-efficiency air filtration (HEPA/ULPA). Stainless Steel Mesh: For high-temperature or corrosive applications. Membrane: For absolute-rated pharmaceutical or semiconductor filtration. Pleats: The media is precisely folded. The height, density, and number of pleats are engineered for optimal flow and dirt-holding capacity. Support Structures: Inner Core (Center Tube): A perforated or mesh tube inside the element that provides structural support, prevents collapse, and allows the clean fluid/air to exit. Outer Cage (Sometimes): A wire mesh

V-Bottom Paper Bag Machine Overview

Here is a detailed explanation of a V-bottom paper bag machine. Simple Definition A V-bottom paper bag machine is an industrial machine that automatically produces paper bags with a distinctive flat, gusseted bottom that forms a "V" shape when viewed from the side. These are the classic, sturdy "shopping bags" or "merchandise bags" you get from boutiques, liquor stores, and department stores. Why is it Called "V-Bottom"? The name comes from the bottom fold structure. If you look at an empty bag from the side, the sealed bottom forms a sharp "V" or gusset, which allows the bag to open into a flat, box-like shape with a stable base that can stand upright. This is different from: Flat-bottom bags: Have a more complex, rectangular bottom (like a brown grocery sack). Block-bottom bags: Have a squarish, block-shaped bottom (like premium gift bags). Pinch-bottom bags: Have a simple, gathered bottom (like a fast-food bag). The V-bottom is a simpler, very effective design for medium-duty retail bags. How the Machine Works (Key Components & Workflow) The machine is a complex system that takes a roll of paper (kraft, recycled, coated, etc.) and performs

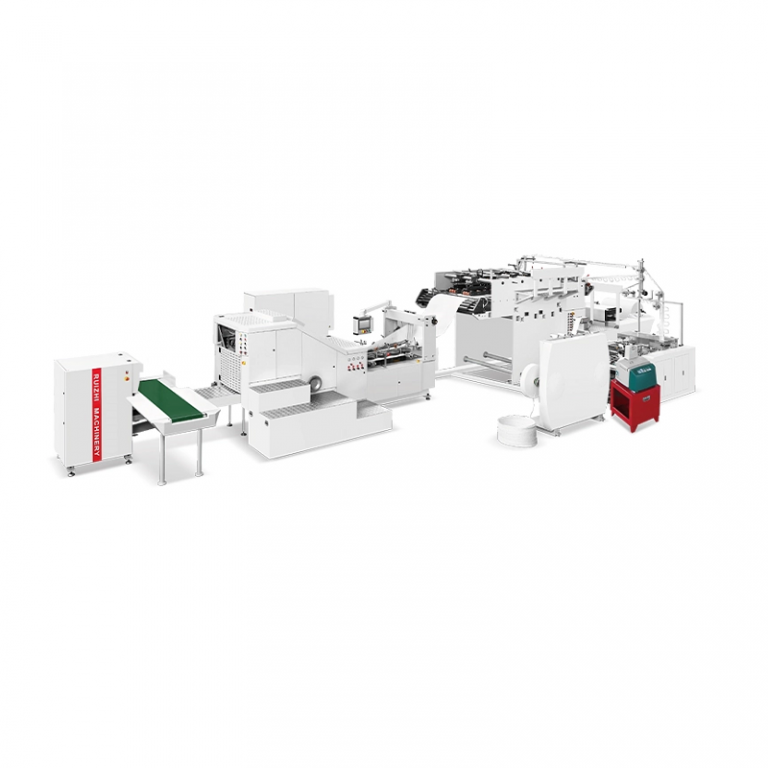

High-Speed Window Paper Bag Machine Overview

A High-Speed Window Paper Bag Machine is a sophisticated piece of industrial equipment designed to automatically produce paper bags with a transparent plastic (or cellophane) window at high production rates. These are the classic bags used by bakeries, pastry shops, gift shops, and retailers for products where visibility is key. Here’s a comprehensive breakdown of what it is, how it works, key features, and considerations. What It Is This machine integrates several processes: paper feeding, gluing, window film feeding and attachment, bottom sealing, and bag forming into one continuous, automated line. "High-speed" typically refers to machines producing 80 to 400+ bags per minute (BPM), depending on the complexity and size of the bag. Key Components & Workflow Paper Unwind Stand: Holds a large roll of kraft paper (white or brown, often recycled or virgin). Printing Unit (Optional): Some machines have a flexographic printing unit for in-line branding or logos. Window Film Unwind: Holds a roll of transparent film (usually OPP, cellulose, or PET). Gluing System: Applies adhesive (cold or hot melt) in precise patterns. Window Patching: Glue is applied to the paper in a rectangular pattern where the

What is multi-axis CNC machining?

Multi-axis CNC machining is an advanced form of computerized manufacturing where a cutting tool or a workpiece can move in four or more directions (axes) simultaneously to produce highly complex parts with exceptional precision and efficiency. To understand it, let's break it down: Core Concept: Beyond the Basic 3 Axes Basic CNC (3-Axis): The cutting tool moves in three linear directions: X (left-right), Y (front-back), and Z (up-down). The workpiece is stationary. It's excellent for machining parts from one side at a time but requires manual repositioning for complex geometries. Multi-Axis (4, 5, 9+ Axis): Adds rotational axes to the linear ones. This allows the cutting tool to approach the workpiece from virtually any angle without manual intervention. Common Multi-Axis Configurations: 4-Axis CNC Machining: Axes: X, Y, Z + A-axis (rotation around the X-axis). What it does: The workpiece rotates, allowing machining on multiple sides or for creating cylindrical features like cam lobes or helical grooves. 5-Axis CNC Machining (The most prevalent and versatile): Axes: X, Y, Z + A-axis (rotate around X) + B-axis (rotate around Y) or C-axis (rotate around Z). Two Main Types: 3+2 Machining (Indexed 5-Axis): The tool or table tilts to a fixed angle and then

Understanding Impeller Blanks in Turbomachinery Manufacturing

An impeller blank is a crucial intermediate stage in the manufacturing of an impeller, which is the rotating component of a pump, compressor, mixer, or turbine that moves fluid. Here’s a detailed breakdown: Simple Definition An impeller blank is the raw, pre-machined form of an impeller. It has the basic overall shape and dimensions but none of the final, precise hydraulic features (like blade profiles, channels, and surfaces) that are critical for its pumping performance. It's essentially the "rough draft" or the starting workpiece. Analogy Think of it like a block of marble for a sculptor. The blank is the raw block, sized and shaped roughly for the statue. The final machining and polishing are what turn it into the detailed, functional artwork. Key Characteristics of an Impeller Blank: Near-Net Shape: It is manufactured to be very close to the final impeller's outer dimensions, minimizing the amount of material that needs to be removed during final machining. No Functional Surfaces: The blades are typically solid wedges or have a very rough shape. The critical inlet and exit angles, blade curves, and flow passages are not yet formed. Material: Made

What is high speed impeller?

Here is a detailed explanation of a high-speed impeller, covering what it is, why speed matters, its design, and applications. Core Definition A high-speed impeller is a rotating component designed to transfer energy to a fluid (liquid or gas) by operating at very high rotational speeds, typically measured in thousands or even tens of thousands of revolutions per minute (RPM). The primary function is to dramatically increase the pressure, velocity, or both of the fluid passing through it. The term "high-speed" is relative to the application. For a large centrifugal water pump, 3,600 RPM might be high. For a turbocharger or a blood pump, "high-speed" can mean over 100,000 RPM. Why High Speed Matters: Key Advantages High Pressure Generation: The energy imparted to the fluid is proportional to the square of the tip speed of the impeller blades. Doubling the rotational speed can quadruple the pressure rise. This is crucial for applications like boosting, compression, and overcoming high system resistance. Compactness & High Power Density: A small impeller spinning very fast can move as much fluid or generate as much pressure as a much larger, slower-moving impeller. This allows

What Industries Use Pre-filters?

Pre-filters, as the "first line of defense" in air filtration systems, have extremely wide applications, covering almost all areas requiring air purification. Generally speaking, pre-filters are mainly used in any place with central air conditioning, fresh air systems, or air purification equipment. Their primary task is to capture larger particles, protecting downstream medium- and high-efficiency filtration equipment and the air conditioning system itself. The following are the main industries and specific scenarios where pre-filters are used, which can be divided into several categories: 1. HVAC Industry This is the largest and most basic application area for pre-filters. Commercial Buildings: Office buildings, shopping malls, shopping centers, hotels, banks, theaters, stadiums, etc. Pre-filters are installed at the return air vents or fresh air inlets of the central air conditioning systems in these places to filter pollen, catkins, dust, insects, etc., from outdoor air, protecting internal components such as air conditioning condensers and heaters from contamination, extending equipment life, and initially improving indoor air quality. Public Facilities: Subways, airports, train stations, hospital lobbies, schools, libraries, museums, etc. 1. High Traffic Flow: Introducing fresh

What is filter cotton for primary filters?

This is an excellent question that gets to the heart of many filtration systems. In simple terms, filter cotton for primary filters is a thick, fluffy, and porous synthetic material that acts as the first line of defense in a multi-stage filtration system. Let's break down its purpose, characteristics, and uses in detail. Primary Function: Mechanical Filtration The main job of primary filter cotton is mechanical filtration. This means its primary purpose is to physically trap and remove solid debris and particles from the fluid (usually water or air) as it passes through. Think of it like a sieve or a net: Water enters the filter, filled with visible waste like fish poop, uneaten food, and plant matter. The water passes through the dense fibers of the filter cotton. The solid particles are too large to fit through the gaps between the fibers and get trapped. Key Characteristics Material: It's almost always made from synthetic polyester fiber. This is chosen because it is inert (doesn't release chemicals), durable when wet, and has excellent filtering properties. Structure: It's not a woven fabric but a "bulked" or

Low cost Paper bag Making machine

Here is a comprehensive guide to low-cost paper bag making machines, covering the types available, key considerations, and where to find them. Understanding the Types of Low-Cost Machines The term "low-cost" primarily refers to manual and semi-automatic machines. These are perfect for small businesses, startups, NGOs, and home-based industries. They are broken down by the specific function they perform: 1. Paper Bag Making Machine Kits This is the most basic and affordable entry point. It's not a single machine but a set of manual tools. What it is: A kit typically includes a creasing and folding tool, a scoring tool, and a hand-held base for gluing. Cost: $50 - $300 Best For: Ultra-small scale production, artisans, crafters, making a few dozen bags per day. It's more about craftsmanship than mass production. Pros: Extremely low cost, no electricity needed, portable. Cons: Very slow, labor-intensive, inconsistent results if not skilled. 2. Manual Paper Bag Making Machines These are dedicated, hand-operated machines that perform one or two specific functions. What it is: A sturdy table-top machine, usually operated by a hand lever. The most common type is the Bottom Pasting Machine. Cost: $300 - $1,500 Best

Mini Electric Ball Valve with 2 Wire Auto Return

Let's break down the "Mini Electric Ball Valve with 2 Wire Auto Return." This is a common and useful component in many automation and fluid control projects. What It Is In simple terms, it's a small, electrically-operated valve that uses a ball with a hole through it to control the flow of liquid or gas. The key features are: Mini: Indicates a compact size, typically with pipe connections like 1/4", 3/8", or 1/2". This makes it ideal for tight spaces, like in appliances, water dispensers, coffee machines, or small-scale automation. Electric: It's powered by electricity (commonly 12V DC or 24V DC) to open or close, instead of being manually turned. 2 Wire: This is the most important part. It has only two wires for both power and control. Auto Return (or Spring Return): This means the valve has an internal spring. When you apply power, the valve opens (or closes, depending on the model). The moment you cut the power, the spring automatically returns the valve to its default state. How It Works: The "2-Wire Auto Return" Explained The "2-wire auto return" system is brilliantly